electronics manufacturing

In the dynamic world of Electronic Manufacturing, staying ahead means understanding the latest trends and innovations shaping the industry. This comprehensive guide explores the future of electronics manufacturing, highlighting key trends, innovations, and their impact on the global landscape.

Evolution of Electronics Manufacturing

Electronics manufacturing has come a long way from its early days of simple circuit assembly. Today, it encompasses a complex ecosystem of design, production, and assembly processes aimed at delivering cutting-edge electronic products to consumers worldwide. The industry is constantly evolving, driven by advancements in technology, changing consumer demands, and global market dynamics.

Key Trends Shaping the Future

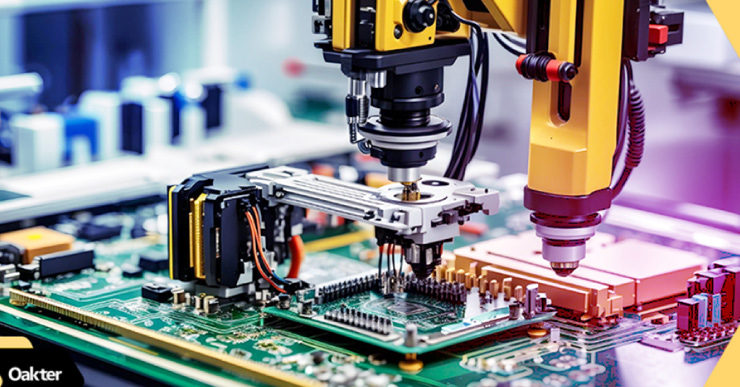

- Automation and Robotics: Automation continues to revolutionize electronics manufacturing, enhancing efficiency, reducing labour costs, and improving product consistency. Robotics, in particular, is increasingly used for tasks ranging from assembly and testing to packaging and logistics.

- Internet of Things (IoT): The IoT is driving demand for smaller, smarter, and interconnected devices. Electronics manufacturers are integrating IoT capabilities into their products, enabling seamless connectivity and enhancing functionality across various applications.

- Green Manufacturing Practices: Sustainability is becoming a critical focus in electronics manufacturing. Companies are adopting eco-friendly practices, such as using renewable materials, reducing waste, and implementing energy-efficient production processes.

- Advanced Materials and Manufacturing Techniques: Innovations in materials science and manufacturing techniques are enabling the development of lighter, stronger, and more durable electronic components. Additive manufacturing (3D printing) is also gaining traction for prototyping and low-volume production.

- Supply Chain Resilience: The COVID-19 pandemic highlighted vulnerabilities in global supply chains. Electronics manufacturers are now prioritizing supply chain resilience, diversifying suppliers, and investing in digital tools for better visibility and agility.

Innovations to Watch

China Electronic Manufacturing Services (EMS)

China remains a powerhouse in Electronic Manufacturing services (EMS), offering a vast network of suppliers, manufacturers, and assembly facilities. EMS providers in China specialize in producing a wide range of electronic components and products, from printed circuit boards (PCBs) to consumer electronics and industrial equipment.

Electronic Manufacturing Services Definition

Electronic Manufacturing Services (EMS) encompass a range of services provided by contract manufacturers who design, assemble, test, and distribute electronic components and products for OEMs (Original Equipment Manufacturers). EMS providers play a crucial role in accelerating time-to-market, reducing production costs, and ensuring quality standards.

Printed Circuit Board Manufacturers In China

China is home to numerous printed circuit board (PCB) manufacturers known for their expertise, scale, and competitive pricing. These manufacturers produce PCBs of varying complexities. Catering to diverse industries such as telecommunications, automotive, aerospace, and consumer electronics.

China Printed Circuit

Printed circuit boards (PCBs) manufactured in China are renowned for their quality, precision, and cost-effectiveness. China’s PCB industry benefits from advanced manufacturing capabilities, a skilled workforce, and a robust supply chain ecosystem, making it a preferred destination for global electronics companies.

The Future Outlook

Looking ahead, the future of electronics manufacturing is poised for continued innovation and growth. Emerging technologies like artificial intelligence (AI). Augmented reality (AR). Quantum computing is expected to transform the industry further. Enabling faster product development. Improved performance and enhanced user experiences.

Challenges and Opportunities

While the future holds promise. Electronics manufacturers also face challenges such as geopolitical tensions. Regulatory complexities and evolving consumer preferences. Successfully navigating these challenges requires agility, innovation, and strategic partnerships across the supply chain.

Conclusion

The future of electronics manufacturing is shaped by innovation, technological advancement, and global collaboration. Understanding and embracing key trends such as automation, IoT integration, and sustainable practices will be crucial for staying competitive in an increasingly interconnected world. As industry leaders and innovators continue to push boundaries, the possibilities for electronics manufacturing are limitless, promising exciting opportunities for growth and transformation.

In conclusion, staying informed and adaptable is essential for thriving in the evolving landscape of electronics manufacturing. By embracing emerging trends and innovations, companies can position themselves at the forefront of innovation and meet the demands of tomorrow’s tech-savvy consumers.